A. Introduction

Wood materials act after the surrounding climate, the main factor is the relative humidity (RH, %).

High humidity means the wood – expands; low humidity – it shrinks.

Due to this natural property you must pay attention to the instructions below.

B. Check before installation

You find additional information to each section further below:

- Store the packages in the future room climate and open package after package when you install.

- This floor will be floating installed,i.e. keep always a distance to all fixed construction parts.

- Check your floor construction.it must be dry,clean, firm and even,eliminate always wall to wall carpets and investigate the floor.

- Choose underlay materials (read carefully below!) according to your own situation – all floors are unique!

- Measure the room, decide installation direction.Note the limitations as per below – due to natural behavior of wood!

- Check you floor continuously during the installation.Installed defect boards can easily be replaced – cannot be complainted!

- Keep always the right room climate 45-60 % RH at 18-24 °C.

- Maintain/clean your FLOOR correct and you will enjoy the floor.

C. Floating Installation

Your floor is made to be installed floating without glue:

- Begin laying in the left-hand corner. Place the floorboard 4-6mmfrom the left wall. The distance to the wall in front (4-6mm) is not important because the flooring can be pushed into place at a later stage.

- Press the end section of the next floorboard at an angle to the first one, then lay down. Complete the first row in the same matter.

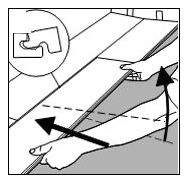

- Place the final floorboard face down and the short side without the locking strip towards the wall. The distance to the wall should be 4-6mm. Mark where the floorboard is to be cut.

- Place the floorboard face down on the work surface and cut to size using a pad under 1 saw. Use a fine toothed type if you are using a hand saw. In this case, cut the floorboards face up.

- Use a cut piece of board from the previous row to start the next row. This must be at least30 cmlong. If the piece is too short, start with a new board, cut in half. Always ensure that the end joints are staggered at least 30 cm.

Pingback: hydroxychloroquine tab 200mg

Pingback: hydroxychloroquine 200mg coupons

Pingback: hydroxychloroquine dosage coronavirus

Pingback: ivermectil substitute over counter walgreens

Pingback: generic priligy online

Pingback: stromectol for urinary tract infection

Pingback: prednisone 1000mg

Pingback: plaquenil and clav

Pingback: ivermectin for dental infection

Pingback: stromectol amazon

Pingback: ivermectin tablets for sale

Pingback: ivermectin pills for humans oral

Pingback: stromectol 6 mg for sale

Pingback: can you purchase viagra over the counter in canada

Pingback: meritroyalbet

Pingback: madridbet

Pingback: eurocasino

Pingback: meritroyalbet

Pingback: 2surfing

Pingback: meritroyalbet

Pingback: meriking

Pingback: madridbet

Pingback: meritking

Pingback: grandpashabet

Pingback: fuck google

Pingback: Leandro Farland

Pingback: Chirurgie Tunisie

Pingback: Chirurgiens esthétique Tunisie

Pingback: National Chi Nan University

Pingback: Oracle Academy

Pingback: برنامج إدارة الأعمال في مصر

Pingback: برنامج التسويق

Pingback: برنامج التسويق بجامعة المستقبل بمصر

Pingback: Finance and accounting programs in Egypt

Pingback: كلية الاقتصاد والعلوم السياسية

Pingback: الاقتصاد

Pingback: Pharmacy Practice and Clinical Pharmacy

Pingback: Arranging workshops and conferences in coordination with internal faculty of pharmacy departments

Pingback: oral and maxillofacial surgery department

Pingback: Experienced professional instructors

Pingback: الحضور والغياب

Pingback: fue

Pingback: Student Success

Pingback: Building Strong Partnerships with Industry

Pingback: FUE

Pingback: Get in Touch with Faculty of EComputers and Information Technology

Pingback: FCIT Scholarships and Financial Aid

Pingback: fue

Pingback: community development

Pingback: Faculty of Engineering and Technology

Pingback: best university in egypt

Pingback: برامج الإقامة في طب الأسنان

Pingback: Admissions process

Pingback: Transfer students admissions to future university

Pingback: امتحانات القبول لجامعة المستقبل

Pingback: Transfer students admissions to future university

Pingback: Entrance exams for future university

Pingback: fue

Pingback: Dental Implant Courses

Pingback: كلية الحاسبات والمعلومات

Pingback: Academic Appeals

Pingback: best university in egypt

Pingback: Periodontal Continuing Education

Pingback: https://www.kooky.domains/post/web3-domain-name-registration-how-to-get-started

Pingback: https://www.kooky.domains/post/what-are-web3-domains-used-for

Pingback: وظائف خريجي ماجستير إدارة الأعمال في مصر

Pingback: Ethical technology practices

Pingback: منح ماجستير إدارة الأعمال في مصر

Pingback: Seattle University

Pingback: لوائح كلية الاقتصاد والعلوم السياسية

Pingback: Professional ethics

Pingback: Faculty Building

Pingback: قسم علم الأدوية

Pingback: كلية الصيدلة جامعة المستقبل بمصر

Pingback: Dental technology

Pingback: منهج الهندسة

Pingback: الهندسة المعمارية

Pingback: Career Fairs

Pingback: Network Administrator

Pingback: Web Development

Pingback: social activities

Pingback: Endodontic Training

Pingback: Online MBA program in Egypt

Pingback: Maillot de football

Pingback: Maillot de football

Pingback: Maillot de football

Pingback: Maillot de football

Pingback: Maillot de football

Pingback: Maillot de football

Pingback: Maillot de football

Pingback: Maillot de football

Pingback: Maillot de football

Pingback: Maillot de football

Pingback: Maillot de football

Pingback: Maillot de football

Pingback: Maillot de football

Pingback: Maillot de football

Pingback: SEOSolutionVIP Fiverr

Pingback: SEOSolutionVIP Fiverr

Pingback: strisce led corridoio

Pingback: Luce lineare LED

Pingback: Luce lineare LED

Pingback: parcour du combattant

Pingback: tomate musculation

Pingback: dalle amortissante 100x100

Pingback: cortexi

Pingback: Fiverr Earn

Pingback: Fiverr Earn

Pingback: Fiverr Earn

Pingback: Fiverr Earn

Pingback: Fiverr Earn

Pingback: Fiverr Earn

Pingback: Fiverr Earn

Pingback: fiverrearn.com

Pingback: fiverrearn.com

Pingback: fiverrearn.com

Pingback: fiverrearn.com

Pingback: Advance-Esthetic LLC

Pingback: fiverrearn.com

Pingback: kos daftar sdn bhd online murah ssm

Pingback: fiverrearn.com

Pingback: TLI

Pingback: freight class calculator

Pingback: ikaria lean belly juice buy

Pingback: weather

Pingback: weather tomorrow

Pingback: fiverrearn.com

Pingback: french bulldog puppies

Pingback: fiverrearn.com

Pingback: fiverrearn.com

Pingback: exotic bullies

Pingback: exotic bullies

Pingback: bernedoodles

Pingback: golf cart rental isla mujeres

Pingback: jute vs sisal rug

Pingback: seo in Saudi Arabia

Pingback: seo in Qatar

Pingback: What are the disadvantages of joining gym cialis vs levitra?

Pingback: Seo marketing

Pingback: Professional Piano Disposal

Pingback: Piano Storage Units

Pingback: Private universities in Egypt

Pingback: Top university in Egypt

Pingback: Top university in Egypt

Pingback: Top university in Egypt

Pingback: Top university in Egypt

Pingback: Private universities in Egypt

Pingback: Top university in Egypt

Pingback: Best university in Egypt

Pingback: Private universities in Egypt

Pingback: Private universities in Egypt

Pingback: Best university in Egypt

Pingback: isla mujeres golf cart rental

Pingback: isla mahara

Pingback: french bulldog puppies for sale

Pingback: micro french bulldog for sale

Pingback: french bulldog adoption

Pingback: rescue french bulldog

Pingback: jewelry

Pingback: french bulldog accessories

Pingback: Medications and Immune System Support - Boosting Body Defenses price of Azithromycin?

Pingback: teacup french bulldog

Pingback: What is the relationship between genetics and cancer risk dapoxetine 60 mg sildenafil 100mg online?

Pingback: brindle french bulldog

Pingback: Breaking Barriers - Medications for Mental Health Empowerment Cenforce 200 sildenafil citrate?

Pingback: Cell phone repair Tustin

Pingback: Mail in phone repair

Pingback: french bulldogs puppies for sale texas

Pingback: Sterling silver heart earrings

Pingback: future university

Pingback: future university

Pingback: future university

Pingback: future university

Pingback: future university

Pingback: future university

Pingback: future university

Pingback: The Microbiota-Gut-Brain Axis - Mental Health Connections stromectol ivermectin?

Pingback: rent a golf cart isla mujeres

Pingback: houston frenchies

Pingback: frenchie ring

Pingback: embroidered vintage sweatshirt

Pingback: multisbobet

Pingback: What is the flat tummy walk Cenforce 200 side effects?

Pingback: How do you make him always want to talk to you Cenforce?

Pingback: Can you have twins vaginally Cenforce brand?

Pingback: How many hours should I walk to achieve 10000 steps order Cenforce online?

Pingback: Careers in Medical Research - From Bench to Bedside order stromectol over the counter?

Pingback: Medications and Skin Rejuvenation - Unveiling Youthful Radiance furosemide 40 mg tablets?

Pingback: Complementary Therapies in Cancer Care - Integrating Holistic Healing order generic Cenforce?

Pingback: french bulldogs

Pingback: FiverrEarn

Pingback: Fiverr.Com

Pingback: Fiverr.Com

Pingback: merle french bulldog

Pingback: best university Egypt

Pingback: Medications and Precision Medicine - Tailoring Treatments to Individuals vidalista vs cialis?

Pingback: golf cart rental isla mujeres

Pingback: french bulldog puppies

Pingback: bulldog frenchie puppies

Pingback: buy cialis with dapoxetine online?

Pingback: isla mujeres golf cart rental

Pingback: Business improvement consultancy

Pingback: Medications - Empowering Patients in Their Health Journeys stromectol cheap?

Pingback: french bulldogs for sale in austin

Pingback: french bulldog puppies for sale in texas

Pingback: Medications and Gut Health - Cultivating a Balanced Microbiome kamagra 100mg?

Pingback: Warranty

Pingback: Piano restoration company

Pingback: Piano restorations

Pingback: FUE

Pingback: FUE

Pingback: FUE

Pingback: FUE

Pingback: FUE

Pingback: Furniture protection

Pingback: Discreet moving

Pingback: Storage solutions

Pingback: Efficient moving

Pingback: pcfinancial ca activate

Pingback: Destinycard.com activate

Pingback: Medications and Sports-Related Injuries - Speeding Up Recovery viagra paypal canada?

Pingback: Classic Books 500

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: Fiverr

Pingback: Fiverr.Com

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: Medications and Sexual Health - Restoring Intimacy and Wellness buy furosemide 20 mg over the counter?

Pingback: New Medications Show Promise in Treating Common Health Conditions Azithromycin allergy?

Pingback: Media

Pingback: Training Philippines

Pingback: Can antibiotics be used to treat infections in patients with diabetic foot ulcers and osteomyelitis metronidazole 250 mg flagyl?

Pingback: Can antibiotics be used for pelvic inflammatory disease (PID) stromectol online brighter tomorrow?

Pingback: Sefton Playclub

Pingback: Pupuk Anorganik terpercaya dan terbaik melalui pupukanorganik.com

Pingback: Pupuk Organik terpercaya dan terbaik di pupukanorganik.com

Pingback: pupuk terbaik adalah di pupukanorganik.com

Pingback: What foods help conceive twins Cenforce 100mg us?

Pingback: Unisex Trendy Custom Tees/Apparel

Pingback: partners

Pingback: Should I lie down if my blood pressure is high purchase lasix generic?

Pingback: skin care products

Pingback: best support blood sugar

Pingback: prodentim reviews

Pingback: claritox

Pingback: fast lean pro official website

Pingback: tea burn

Pingback: nootopia collagenius reviews

Pingback: foliprime reviews

Pingback: where to buy fluxactive complete

Pingback: Political Science

Pingback: Can antibiotics be used for ventilator-associated pneumonia (VAP) plaquenil 200 mg

Pingback: What is the closest thing to OTC steroids ventolin inhaler for asthma

Pingback: french bulldog breeder

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: live sex cams

Pingback: live sex cams

Pingback: kamagra 100 mg oral jelly

Pingback: live sex cams

Pingback: live sex cams

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: buy kamagra uk paypal

Pingback: french bulldog dogs for sale

Pingback: What are signs that a man is healthy??

Pingback: Do you sleep more after a breakup??

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: pearl

Pingback: web design

Pingback: Best University in Yemen

Pingback: Situs Slot Online

Pingback: Slot Thailand

Pingback: Scientific Research

Pingback: Kuliah Termurah

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: FiverrEarn

Pingback: buy priligy 60 mg - How do you stimulate a man's mind?

Pingback: safegenericpharmacy vidalista

Pingback: vardenafil online

Pingback: fildena super active отзывы

Pingback: viagra for men under 30

Pingback: Generator Repair near me Leeds

Pingback: cheap sex cams

Pingback: cenforce 200 morgen in huis

Pingback: cenforce

Pingback: fildena 150 fortune healthcare order now

Pingback: fullersears.com

Pingback: can i buy priligy in mexico

Pingback: vidalista 40mg

Pingback: canine probiotics

Pingback: buy furosemide 40mg generic

Pingback: tadalista 20mg

Pingback: revatio medicine

Pingback: atorvastatin 10 mg side effects

Pingback: dapoxetine 60 mg tablet

Pingback: live sex cams

Pingback: live sex cams

Pingback: testosterone hormone gel

Pingback: nolvadex for sale

Pingback: rare breed-trigger

Pingback: What can replace antibiotics hydroxychloroquine for arthritis?

Pingback: prestanombres

Pingback: Luxury rent a car Dubai

Pingback: 늑대닷컴

Pingback: Agen slot online

Pingback: One Peace AMV

Pingback: nang sydney

Pingback: freelance web developer

Pingback: allgame

Pingback: 918kiss

Pingback: หวย24

Pingback: moisturizer

Pingback: bulldog in clothes

Pingback: pg slot

Pingback: leak detection london

Pingback: la bonne paye règle

Pingback: Raahe Guide

Pingback: aplikasi judi online24jam terpercaya slot

Pingback: aplikasi slot

Pingback: resort lake placid

Pingback: upstate hotels

Pingback: priligy over the counter

Pingback: megagame

Pingback: weight loss drops

Pingback: weight loss injection

Pingback: vidalista 80 mg price in india

Pingback: contratar sicario

Pingback: SaaS Attorney

Pingback: itsMasum.Com

Pingback: signaler des mails frauduleux

Pingback: deux categorie de logiciel malveillant

Pingback: systeme d'exploitation

Pingback: formation rémunérées

Pingback: apprendre le codage

Pingback: POLEN FÜHRERSCHEIN

Pingback: Nangs delivery

Pingback: chauffe eau Tours

Pingback: itsmasum.com

Pingback: chat with strangers online

Pingback: sildenafil 50mg price

Pingback: boys chat

Pingback: cenforce

Pingback: vidalista 60mg

Pingback: itsmasum.com

Pingback: itsmasum.com

Pingback: itsmasum.com

Pingback: itsmasum.com

Pingback: buy lasix online from canada

Pingback: flagyl metronidazole 500mg pills

Pingback: buy vidalista

Pingback: cenforce 200mg online

Pingback: cenforce 200 india

Pingback: fildena 50 mg online

Pingback: tadalafil-vidalista 40 mg

Pingback: vidalista 40

Pingback: order fildena 100mg online

Pingback: hcq

Pingback: Buying Generic clomid no prescription

Pingback: Buy clomiphene

Pingback: priligy dapoxetine for sale

Pingback: Film institutionnel Nantes

Pingback: montreal jobs

Pingback: ny jobs central

Pingback: jobs

Pingback: stockholm jobs

Pingback: clomid for women

Pingback: Generic clomid pills

Pingback: clomiphene citrate 50 mg for men

Pingback: priligy canada

Pingback: priligy online

Pingback: kamagra jelly pack

Pingback: vidalista 20

Pingback: vidalista 20

Pingback: buy vidalista online

Pingback: advair diskus how to use

Pingback: advairhfa

Pingback: vidalista 60 mg for sale

Pingback: cenforce 200

Pingback: Cenforce 100mg without preion

Pingback: erectiepillen cenforce 200

Pingback: buy kamagra oral jelly thailand

Pingback: where to buy ivermectin for humans

Pingback: cenforce 200mg amazon

Pingback: cenforce d 100

Pingback: cenforce D tablet

Pingback: Sildenafil 100 mg

Pingback: cenforce online

Pingback: super kamagra

Pingback: cialis no prescription

Pingback: Teva Sildenafil

Pingback: eriacta or kamagra

Pingback: webcam sex

Pingback: free sex cams

Pingback: Kampus Islami

Pingback: lasix online order

Pingback: french bulldog texas

Pingback: advair diskus 500/50 mcg (red)60s

Pingback: A Yemeni Arab Journal Indexed by Scopus and ISI

Pingback: First Yemeni University to Enter the Times Higher Education Impact Rankings 2024

Pingback: افضل جامعة يمنية

Pingback: 918kiss

Pingback: Sildenafil Citrate 100mg

Pingback: daruvir

Pingback: sildenafil 100mg drug

Pingback: goedkoopste vidalista 80

Pingback: cenforce bestellen

Pingback: buy ventolin

Pingback: iverhope 6 mg

Pingback: generic stromectol